By Brian Blair

This article was published in Nines 364. We are making it available here for reference by the Saab community. Join SCNA today to get more content like it.

One of my earliest Saab experiences was back in the early 90’s during my first week in college at UVM in Burlington Vermont. I was riding with a group of brand new acquaintances on some long forgotten quest (probably for food or beer), and our driver was the proud owner of a new Saab 9000 turbo that she’d received as a high school graduation present earlier that summer. I remember forming an immediate obsession for Saab in that single ride. From the initial impressions of the smart Scandinavian styling, to the smell and feel of the new leather and the bass pumping out of the Clarion stereo with its mesmerizing spectrum analyzer, but most of all from the rush of the acceleration that felt like you were riding a wave of power as the turbo spooled hard and pushed you back into the seats. I honestly can’t remember the exact group of people I was riding with at the time, but I remember that Saab and I was completely smitten. I vowed to myself that I would own one as soon as I graduated and found gainful employment (two weeks after graduating from UVM I got a small loan from a family member and purchased my first Saab, a 1989 Saab 9000 CD in Malachite green). Over the years I have owned many Saabs, and if you are a little bit like me then you might find yourself hunting for ways to hold on to that original exhilaration you felt with your first experience in a turbocharged Saab, which brings us to the focus of this discussion – custom tuning your Saab for more power!

To understand how we can increase the performance of your engine through custom tuning, we need to first discuss some basics. I will be necessarily brief to cover as much as possible in this single article, but I will include some good references at the end to help you explore further if you so desire.

To begin with, you can think of a gasoline combustion engine as an air pump and the amount of power and torque an engine can generate is largely determined by how much air it can move in a single combustion cycle. Almost every modern turbocharged engine today uses some sort of torque control strategy that is based on this measurement. By directly measuring and/or mathematically modeling how much air is stuffed into a cylinder for each combustion event the engine management software can calculate how much torque is instantaneously generated. By multiplying that torque for each combustion event times the engine speed we can also calculate the amount of power that is being generated. Hence, the software that controls your engine both knows and can precisely regulate how much power and torque it is making at any given moment.

So why would any engine manufacturer choose to limit the maximum power and torque their engine produces to something less than what the engine is actually capable of generating? There are actually many reasons for this, not limited to just warranty and durability considerations. When a manufacturer such as Saab (*cough*GM) decides to design and build a new engine, they invest many millions of dollars in the development and infrastructure to manufacture the engine. This is a long costly process, and the “lifespan” of an engine in its intended applications may span a decade or more. To help protect their investment, the manufacturer wants to bake in some ability to react to market forces (like competitor offerings) and give you incentives to upgrade to newer models by increasing the power output of the engine modestly without needing to redesign the engine or retool a manufacturing facility. For this reason it is a common practice to release the earliest iterations of an engine at a lower power and torque output than what it was ultimately designed, tested and validated to. You can see this process in action with the 2.8T V6 turbo engine used in the 2006+ Saab 9-3/9-5/9-4 models. In 2006 the 9-3 Aero (in North America) was initially released with a 250hp calibration, in 2007 this was bumped up to 255hp, then in 2008 it was bumped again to 280hp. Aside from a few minor differences, the engines were identical and the difference in power was accomplished simply by updating the various torque limiters in the factory engine calibration software.

So essentially, when it comes to custom tuning, we are in part short circuiting the life cycle of the engine to give you what the engine is actually capable of generating. It is not quite as simple as just removing all the torque limiters;, that would be irresponsible and would most likely result in your Saab running poorly at best or experiencing catastrophic failure at worst. But done properly, we can extract the maximum potential of your engine with minimal risks while maintaining good long term durability.

If you are ready to proceed with a custom tune, there are some basic maintenance items you should complete first to help achieve the best results and minimize potential issues. The manufacturer’s maintenance/ service schedule will provide a checklist of critical items/services that you should have completed based on your vehicle’s mileage – if you purchased the vehicle used and do not have receipts for the major services then I would not assume they have been completed by the previous owner. The most critical items to focus on, in regards to the powertrain performance, will be the engine oil/filter, spark plugs, air filter, transmission fluid (for automatics), coolant and for XWD owners the transfer case fluid, rear differential fluid and eLSD fluid/filter. Of these items, probably the most critical is installing a fresh set of spark plugs, and adjusting the gaps tighter than stock for any performance tune running increased boost pressure (gap and heat range recommendations for specific models can be found on my website under the User Forums sections).

The influence your spark plugs have on the performance of your engine cannot be overstated, so I want to take a moment to discuss them in more detail. Understanding and paying attention to these details during installation can have a profound effect on the power output of your engine, even before installing a custom calibration file.

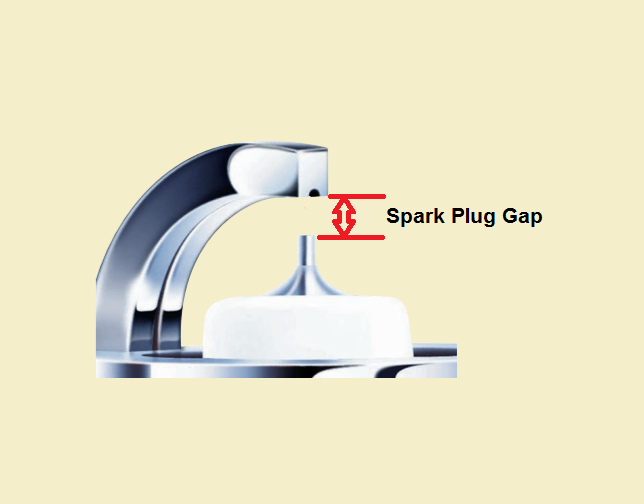

The electrode gap on a traditional spark plug is the space between the center (bottom) and ground (top/ strap) electrodes. On most Saabs, the stock factory gap is set at approximately 0.95 – 1.05 millimeters. The gap distance is optimized based on a few factorsincluding the energy storage capacity of the ignition coils, the compression ratio of the engine and the amount of maximum boost pressure the engine will operate under. When we increase the boost pressure of the engine with a performance calibration, we are stuffing more air into each cylinder which is then compressed further prior to ignition. An engine running 7 psi of boost on a stock tune will begin with ~ 7psi of pressurized air in each cylinder, which is compressed further on the compression stroke based on the compression ratio of the engine (ie, 10:1 compression ratio for the Saab 2.8T). By the time the spark plug is fired, the pressure in the cylinder will reach a few hundred psi. If we increase the boost pressure, say by 10 psi over stock the pressure, the final cylinder pressure just before spark ignition occurs can actually increase by a couple hundred psi over the stock tune conditions. What you may not immediately understand is that air has an electrical resistance that varies significantly with pressure. As we increase the cylinder pressure we actually increase the electrical resistance of the air, and thus make it harder to fire a spark across the gap on the spark plug. As your car ages, the electrical coils also deteriorate and the maximum charge available for the spark event may be significantly reduced compared to when the coil packs were new. The combination of these two factors is why you may experience misfires after installing a performance tune, even though the car was running fine on the stock boost levels. We can address part of this issue by reducing the gap on the spark plugs which reduces the electrical resistance working against the energy discharge from the ignition coils, thus making it easier to fire the spark under the higher cylinder pressure.

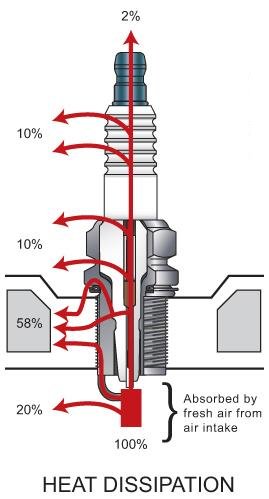

The next aspect of your spark plugs that is not commonly understood is the fact that they need to dissipate heat efficiently to operate within the specific temperature range they were designed for. Too hot and the tip of the plug can ignite your fuel before the spark ignition event, which is known as pre-ignition knock. Too cold and the plugs will carbonize and foul. Spark plugs dissipate heat by transferring it through contact with the cylinder head. Many spark plugs have special crush washers (the cylinder head design will dictate this). These spark plugs must be installed with enough force to crush the washers, or there will be an air gap that acts as a thermal break that prevents heat from dissipating from the plug. If the plug is installed too loosely, it will run hot and cause pre-ignition knock.

In a real world example, while data logging a customer’s Saab 9-3 Aero I observed that it was showing 5-6 degrees of knock retard when I normally see very little to none. After reviewing the issue with the owner he identified that he just completed the major services himself, including replacing the spark plugs. I decided to pull one of the plugs for inspection and found that it came loose with the lightest effort and in fact all of the plugs had been installed only hand tight. After re-installing the plugs and verifying that the crush washers had seated properly the knock was eliminated. I actually do not use a torque wrench when installing spark plugs – I torque them by feel and remove the plug to examine the crush washers to ensure I tightened the plug sufficiently. Once the washer has been properly crushed you can use a torque wrench for the final install if you wish. Just work on a cold motor and there is little chance that you are going to cause damage to the threads in the aluminum head as long as you use a little common sense. On an older engine with some crud build-up on the spark plug threads you will need to use some moderate additional force (maybe 5 to 10 lb-ft) above the factory torque specification to actually seat the crush washers properly.

Finally, the octane of the fuel you use is absolutely critical to getting the best performance in a turbocharged engine. I can optimize a tune for various octane ratings, but as a rule of thumb make sure to fill up with the highest octane available at the pumps in your area (typically 91 or 93 at minimum).

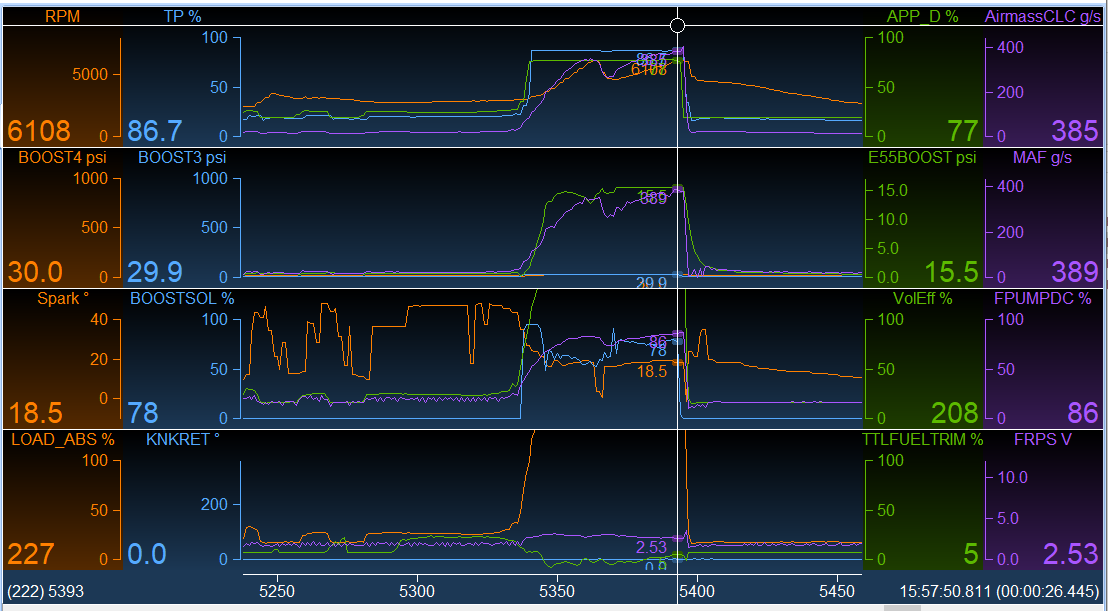

Assuming that you (or your preferred mechanic) followed my prior advice and completed your major services, you should be in relatively good shape to begin the process of performance tuning your Saab. There are still numerous issues that can arise during the tuning process from other aging or weak engine components, but part of a good custom tune involves a knowledgeable powertrain expert reviewing data logs of your engine captured while you drive the car. This is typically accomplished using one of our handheld tuning systems (or a similar OBD2 diagnostic scan tool with advanced data logging capabilities). Simply flashing a modified calibration to your Saab without the benefit of a tuning specialist’s review of your engine’s data log is likely to result in less than optimal performance, even if you do not have any obvious signs of a problem (no misfires or check engine lights).

If you do experience more significant issues even an experienced mechanic may struggle to properly diagnose and understand the root cause without the aid of a performance tuning specialist. A data log captures real time information while you drive the car, including dozens of critical parameters such as wideband air/fuel ratios, fuel pressure, fuel pump output, ignition timing, knock on each cylinder, misfires on each cylinder, boost pressure, volumetric efficiency, oil pressure, coolant temperatures and much more. Armed with that information I can advise you of any issues I observe that are limiting the performance of your Saab, along with additional recommendations on what you can adjust, inspect or replace to get the best performance possible.

Links/Resources:

vermonttuning.com/forums/forum/model-specific-discussions/saab/

NGK Tech Video – How to gap your spark plugs

Gasoline Engine Management 3rd Ed

Robert Bosch GmbH

by Bentley Publishers ISBN 0-8376-1390-6

BRIAN BLAIR (on right) is the sole proprietor of Vermont Tuning LLC, founded in 2009 and located in Sheldon Vermont, where he began offering custom performance calibration services developed for the last generation Saab 9-3 Aero 2.8T . Over the last 12 years his business has greatly expanded the portfolio of supported vehicles to include most late model GM and Saab vehicles as well as select Ford and Volvo models. Brian’s professional experience includes over ten years of powertrain calibration development as well as consulting services to the automotive industry with clients that include a long time Tier 1 supplier to GM.